Sewer Testing

Sewer Line Air Testing and Leak Locating

Complete, Ready To Go System for Testing

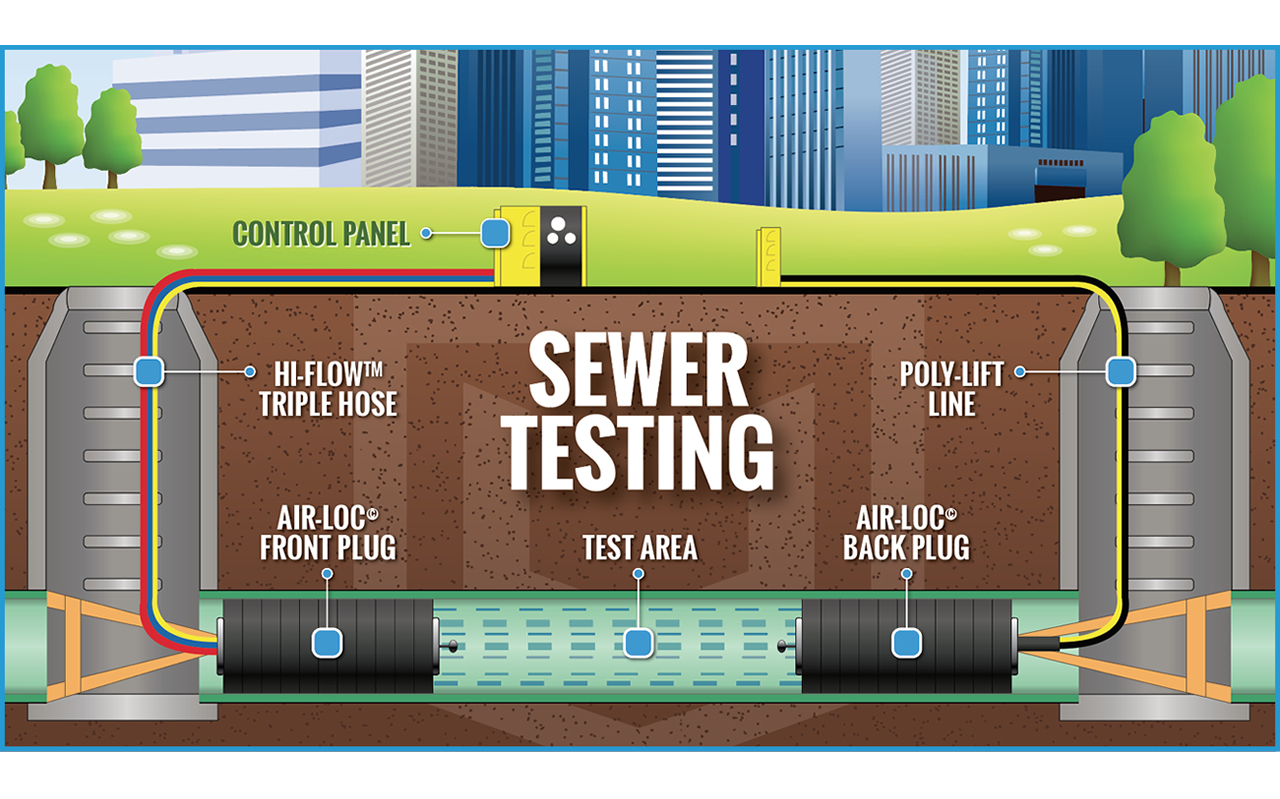

The United Water Works sewer line testing system is a complete system using the Cherne Air-Loc® Low Pressure Air-Testing System. Includes everything you need, ready to go, to perform your sewer line test.

The Benefits of using our Sewer Line Testing System:

- Save time with the ready to go system

- System guaranteed to work

- A positive test for infiltration or exfiltration

- Testing can be performed on various types of sewer pipe including newly installed or preexisting lines

- Cost effective solution

- Verifies the integrity of new sewer lines

- Simple, fast and efficient quality control test for verifying workmanship of newly installed sewer lines

The Cherne Air-Loc® Low Pressure Air-Testing System has been successfully used for testing sewer pipe installations for over 40 years. This method of testing pipe lines has proven to be the fastest, most economical and accurate method of testing pipe. It allows you to perform tests as prescribed by ASTM C 828, C 924, and F 1417.

Cherne's Line Acceptance Kit is used to perform low pressure air tests on newly installed sewer lines. The Line Acceptance Kit includes all items needed to conduct the test, except an air compressor and two pipe plugs.

Included in the Sewer Line Testing:

- Air-Loc testing panel

- Color coded triple hose

- Front and back plug for testing pipes 6" - 18"

- Poly life line

- Storage container

Aqua-Loc® Hydrostatic Test Pump:

Diaphragm Style – Features:

- Hypro® twin diaphragm pump - 9.5 gpm/550 PSI

- Integral manifolds - eliminates leak points

- Pulsation dampener - no need to surge tank

- Enclosed gear reduction - excellent heat dissipation

- 5.5 HP engine

- May be run dry

- Four output pressure settings

- Handles up to 10% chlorine solutions

Optional Testing Supplies Available:

- Long test balls 4"

- T handle mechanical plugs 6" - 12"

- Gripper plugs 4" - 8"

Air-Loc Line Test Procedure:

- Install back plug. Attach poly lift line to pipe plug and place plug in line to be tested. Inflate plug to proper inflation pressure from above ground.

- Insert front plug. Connect triple hose assembly to front plug and insert plug into line. Connect other end of triple hose to Air-Loc® Control Panel.

- Conduct test. Connect air compressor to control panel. Then inflate front plug to proper inflation pressure. Introduce air through control panel until test pressure is achieved. Monitor pressure for the time designated for the test. If the pressure holds for the designated time losing one psi or less, the line passes and is “Accepted."